Steel Door Maufacturing Process

The steel door manufacturing process involves several steps to produce a high-quality, durable, and secure door.

These steps include:

- Material preparation: The process starts with the preparation of steel sheets or panels, which are typically galvanized or coated to provide additional protection against corrosion. These sheets are uncoiled from large rolls and fed into the production line.

- Cutting and shaping: The steel sheets are cut to the required dimensions and shapes using machines such as hydraulic cutting machines, punching machines, or laser cutting machines. Holes for hardware components, such as hinges, locks, and handles, are also created at this stage.

- Bending and forming: The cut steel sheets are bent and formed into door components, such as the door panel, frame, and reinforcements. This is done using bending machines, press brakes, or roll forming machines.

- Assembly: The door components are assembled together, with the core material (usually an insulating material like polyurethane foam or mineral wool) inserted between the steel sheets to create a sandwich-like structure. This provides the door with enhanced thermal and acoustic insulation properties.

- Welding and grinding: The door edges and reinforcements are welded together to form a solid, secure structure. After welding, the seams are ground smooth to ensure a clean, professional finish.

- Surface treatment: The door surface is treated to remove any impurities and enhance its corrosion resistance. This may involve processes such as degreasing, pickling, or phosphating.

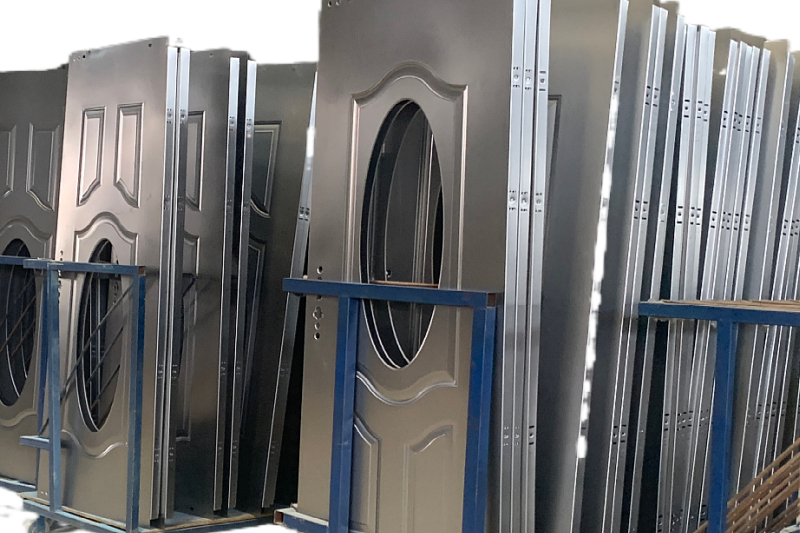

- Priming and painting: The door is primed with a rust-inhibiting primer to ensure proper paint adhesion. After priming, the door is painted or powder-coated with a durable, high-quality finish. This process can be manual or automated, depending on the manufacturer’s capabilities.

- Hardware installation: Hinges, locks, handles, and other hardware components are installed onto the door. The hardware is typically made from metal, such as brass, stainless steel, or aluminum, and is designed to complement the door’s overall appearance and functionality.

- Quality control and inspection: The completed steel door undergoes a thorough quality control inspection to ensure it meets the required standards and specifications. This may involve checking for proper alignment, smooth operation, and correct hardware installation, as well as assessing the door’s overall appearance and finish.

- Packaging and shipping: Once the steel door passes the quality control inspection, it is packaged for shipping. Packaging materials, such as cardboard, plastic wrapping, or foam, protect the door from damage during transit. The door is then shipped to the customer or distributor, ready for installation.

By following this manufacturing process, steel door producers can create high-quality, durable, and secure doors that meet the needs of various residential and commercial applications.