Security Door Press Machine Modern Steel Door Design

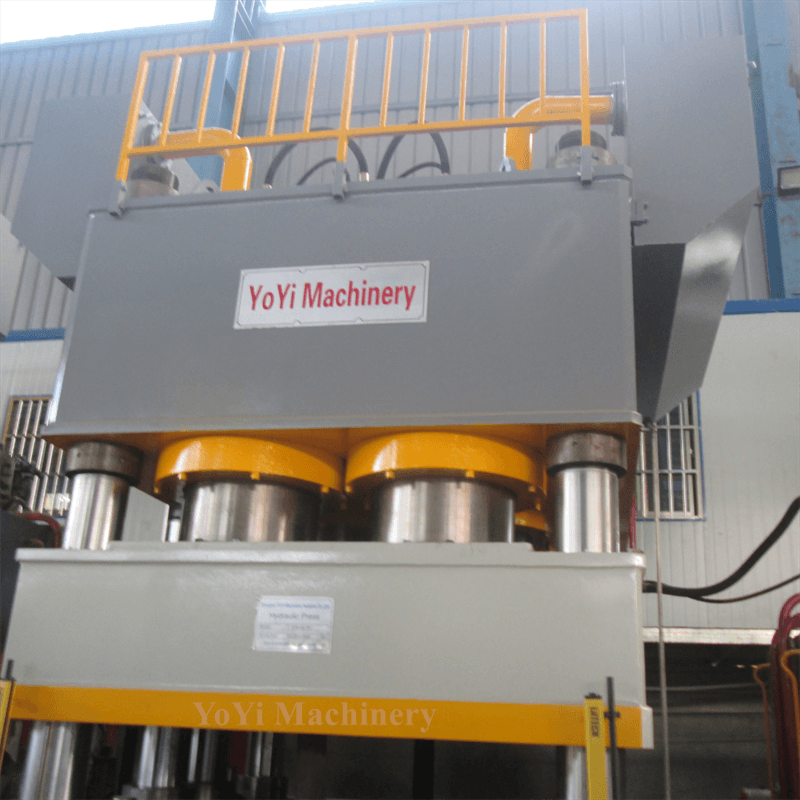

A security door press machine is an industrial machine designed to manufacture security doors made of various materials such as steel or other metals. These security doors are intended to provide enhanced security and protection for residential or commercial properties. This security door hydraulic press applies high pressure to the metal sheets, resulting in strong and aesthetically pleasing security doors.

Key Components:

- Frame: The frame of the security door press machine provides structural support and rigidity, enabling it to withstand the high pressure applied during the door forming process.

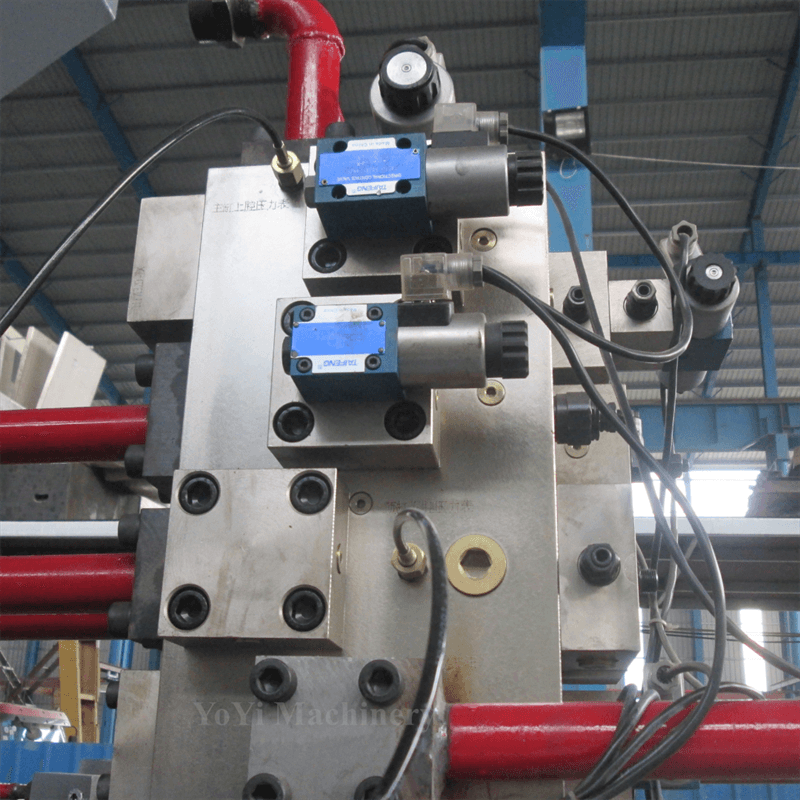

- Hydraulic press system: The press system generates the force required to shape the metal sheets into the desired security door design.

- Security door mold: The security door mold is an essential component of the press machine. It comprises two parts – the cavity and the core – designed to create the desired door shape and pattern when pressed together.

- Pressing table: The pressing table is the surface on which the metal sheets are placed and aligned before the pressing process begins.

- Control system: The control system manages the operation of the security door press machine, including the force applied during the pressing process, the speed of the press, and the duration of the press cycle.

- Safety features: Security door press machines are equipped with safety features such as emergency stop buttons, guards, and interlocks to protect operators from potential hazards during the door manufacturing process.

Operation Security Door Press Machine:

- Prepare the metal sheets: The metal sheets are cut to the required size and thickness according to the security door design specifications.

- Place the metal sheet on the pressing table: The metal sheet is positioned and aligned on the pressing table, ensuring that it is correctly placed in the mold cavity.

- Pressing process: The hydraulic press system applies high pressure to the metal sheet, forcing it into the security door mold cavity. The metal sheet conforms to the shape of the mold, creating the desired security door design.

By following this process, a security door press machine can efficiently produce high-quality security doors that meet the desired specifications and provide enhanced protection for residential or commercial properties.

Main Technical Parameters:

1) Nominal force: 30000 Kn

2) Return force: 425 Kn

3) Slide Stroke: 500 mm

4) Max. working pressure of hydraulic system: 25 Mpa

5) Max. Opening Height: 600 mm

6) Slider Speed

a. Descending: 100-120 mm/s

b. Working: 4-8 mm/s

c. Returning: 100-120 mm/s

7) Effective working table size: 1500 mm × 2500 mm

8) Motor Power: 60KW

9) Structure: three-beam, eight-column, single action.

How to Choose the Right Security Door Press Machine

Selecting the right security door press machine can make all the difference in your manufacturing process. Here are a few factors to consider:

- Production Volume

If you are working on large-scale production, a hydraulic press machine with high pressing power may be the best option. For smaller volumes, a mechanical press machine could be sufficient. - Material Type

Ensure that the press machine you choose is capable of handling the materials you plan to use. Some machines are better suited for steel, while others are designed for softer metals or composite materials. - Maintenance and Support

Look for a machine that comes with reliable support and easy access to replacement parts. Regular maintenance is crucial for keeping the machine running smoothly.

casssia@yoyimachinery.com

casssia@yoyimachinery.com