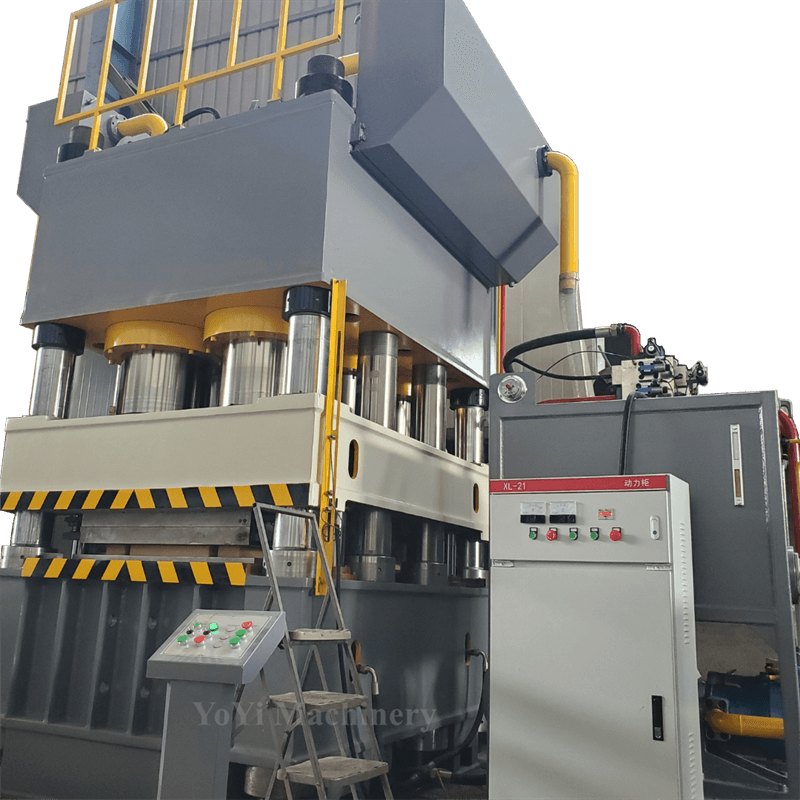

Пресс-форма для штамповки дверей 3000T

3000T Door Press Machine: Revolutionizing Metal Door Manufacturing

The 3000T Door Press Machine is an advanced hydraulic press specifically designed for the manufacturing of high-quality metal doors. Known for its exceptional power and precision, this machine enables manufacturers to create durable, aesthetically pleasing, and perfectly shaped doors. With a 3000-ton pressing capacity, the 3000T door press machine is ideal for handling large-scale production, delivering consistent results, and ensuring a high standard of quality.

What is a 3000T Door Press Machine?

А 3000T Door Press Machine is a large-capacity hydraulic press used in the production of metal doors. It operates by using high-pressure force to mold metal sheets into the desired shape. The “3000T” refers to the machine’s maximum pressure capability of 3000 tons, making it one of the most powerful presses available for industrial use. This immense force ensures precise shaping and embossing of metal doors, allowing for intricate designs and superior durability.

Key Features of the 3000T Door Press Machine

- High Pressure Capacity

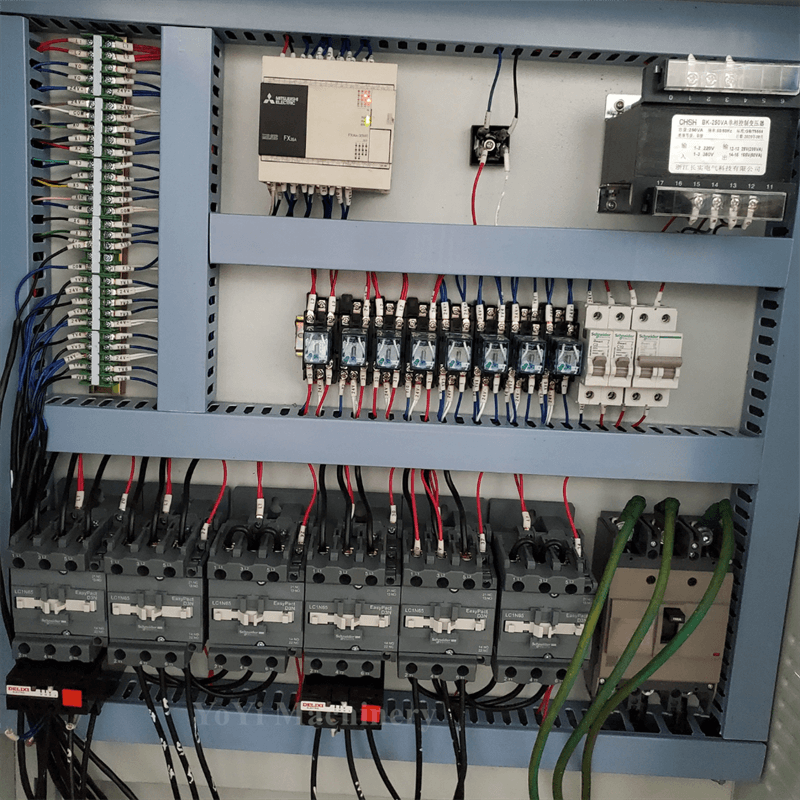

The most notable feature of the 3000T Door Press Machine is its immense pressure capacity. With 3000 tons of force, the machine can easily handle thick and large metal sheets, ensuring a perfect embossing or molding process every time. This high pressure also helps in the production of heavy-duty doors that require extra strength and durability. - Hydraulic System

The machine uses a hydraulic system to generate the necessary pressure. This system ensures smooth and efficient operation, providing manufacturers with precise control over the embossing process. The hydraulic technology also ensures that the force is evenly distributed across the metal, reducing the risk of defects during production. - Versatile Design Capabilities

Whether you’re creating plain, smooth doors or more intricate, textured designs, the 3000T Door Press Machine offers versatility. It can be used for embossing patterns, logos, or even company branding on metal doors, allowing for custom designs tailored to specific customer needs.

How the 3000T Door Press Machine Works

The operation of a 3000T Door Press Machine is straightforward yet highly effective. Here’s an overview of how it works:

- Loading the Metal Sheets

Metal sheets are fed into the machine’s press bed, where they are positioned under the press. The metal can be made of various materials, including steel, aluminum, or stainless steel, depending on the requirements. - Applying Pressure

The machine’s hydraulic system generates up to 3000 tons of pressure. This pressure is applied evenly across the metal, ensuring that it molds into the desired shape. The force can be adjusted depending on the specific needs of the door design and material. - Forming the Design

The press is equipped with molds or dies that shape the metal into the final door design. Whether it’s a flat panel door or a door with intricate embossing, the machine can handle a wide variety of designs and textures. - Finishing Touches

Once the door is shaped, it is removed from the press and checked for quality. Additional processes like painting, coating, or surface treatment may be applied to enhance the appearance and durability of the door.

Applications of the 3000T Door Press Machine

The 3000T Door Press Machine is widely used across various industries for different applications, including:

- Residential Doors

The 3000T Door Press Machine is ideal for producing high-quality residential doors that require both durability and aesthetic appeal. These doors can be customized with unique textures, designs, and finishes. - Commercial Doors

Businesses often require doors that are not only strong but also visually appealing. The 3000T press can create doors that are both functional and stylish, perfect for offices, hotels, and other commercial buildings. - Industrial Doors

For industries that require heavy-duty doors, the 3000T Door Press Machine is an excellent choice. Its immense pressure capacity ensures that the doors are built to withstand harsh environments and heavy usage. - Security Doors

In high-security areas, doors must be tough and resistant to forced entry. The 3000T press can create security doors that are highly resistant to damage, making them ideal for prisons, vaults, and other secure facilities.

Conclusion: The Future of Door Manufacturing with the 3000T Door Press Machine

The 3000T Door Press Machine represents the pinnacle of innovation in the metal door manufacturing industry. Its powerful hydraulic system, customizable design capabilities, and efficient production processes make it an invaluable tool for manufacturers looking to stay competitive. By investing in a 3000T Door Press Machine, businesses can enhance their production capabilities, improve product quality, and meet the growing demand for durable and aesthetically pleasing metal doors. Whether for residential, commercial, or industrial applications, this machine is a must-have for any serious door manufacturer.

Основные технические параметры:

1) Номинальная сила: 30000 кН

2) Возвратное усилие: 425 кН

3) Ход слайда: 500 мм

4) Макс. рабочее давление гидросистемы: 25 МПа

5) Макс. Высота открытия: 600 мм

6) Скорость слайдера

а. По убыванию: 100-120 мм/с

б. Рабочая: 4-8 мм/с

в. Возвращение: 100-120 мм/с

7) Эффективный размер рабочего стола: 1500 мм × 2500 мм

8) Мощность двигателя: 60 кВт

9) Структура: трехлучевая, восьмиколонная, одинарного действия.

casssia@yoyimachinery.com

casssia@yoyimachinery.com